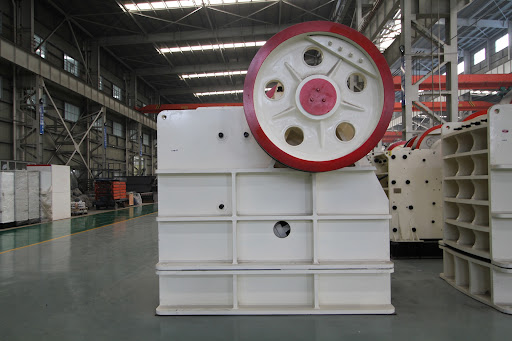

Description

Application:

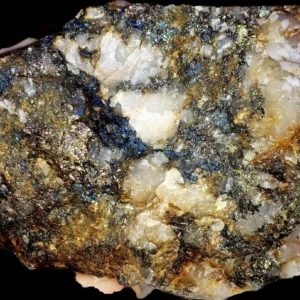

Jaw crushers are essential in industries like mining, quarrying, and recycling for primary crushing of hard materials such as rock, gravel, and concrete. Their robust design and ability to handle high capacities make them a staple in many operations worldwide.

Key Components:

- Fixed Jaw Plate: Stationary part of the jaw crusher.

- Movable Jaw Plate: Moves back and forth to crush the material against the fixed jaw.

- Pitman: Connects the movable jaw to the eccentric shaft.

- Eccentric Shaft: Rotates, causing the movable jaw to move back and forth.

- Toggle Plate: A toggle plate plays a role in adjusting the outlet of the crusher.

Working Principle:

- Feed Material: Rocks or ore are fed into the top of the crusher through a hopper or feeder.

- Crushing: The movable jaw compresses the material against the fixed jaw, crushing it to the desired size.

- Discharge: Once crushed to the appropriate size, the material exits the crusher through the bottom, ready for further processing.

Advantages:

- High Efficiency: Capable of crushing large amounts of hard material.

- Simple Structure: Easy maintenance and operation.

- Versatility: Suitable for various materials and applications.

Specifications:

|

Model |

Feeder Opening

Size(mm) |

Max. Feeding

Size (mm) |

Outlet adjusting

Size(mm) |

Capacity

(t/h) |

Motor Power

(kw) |

Overall Dimension (mm) |

| PE400x600 | 400×600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500×750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600×900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750×1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900×1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000×1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500×1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |