Description

Applications:

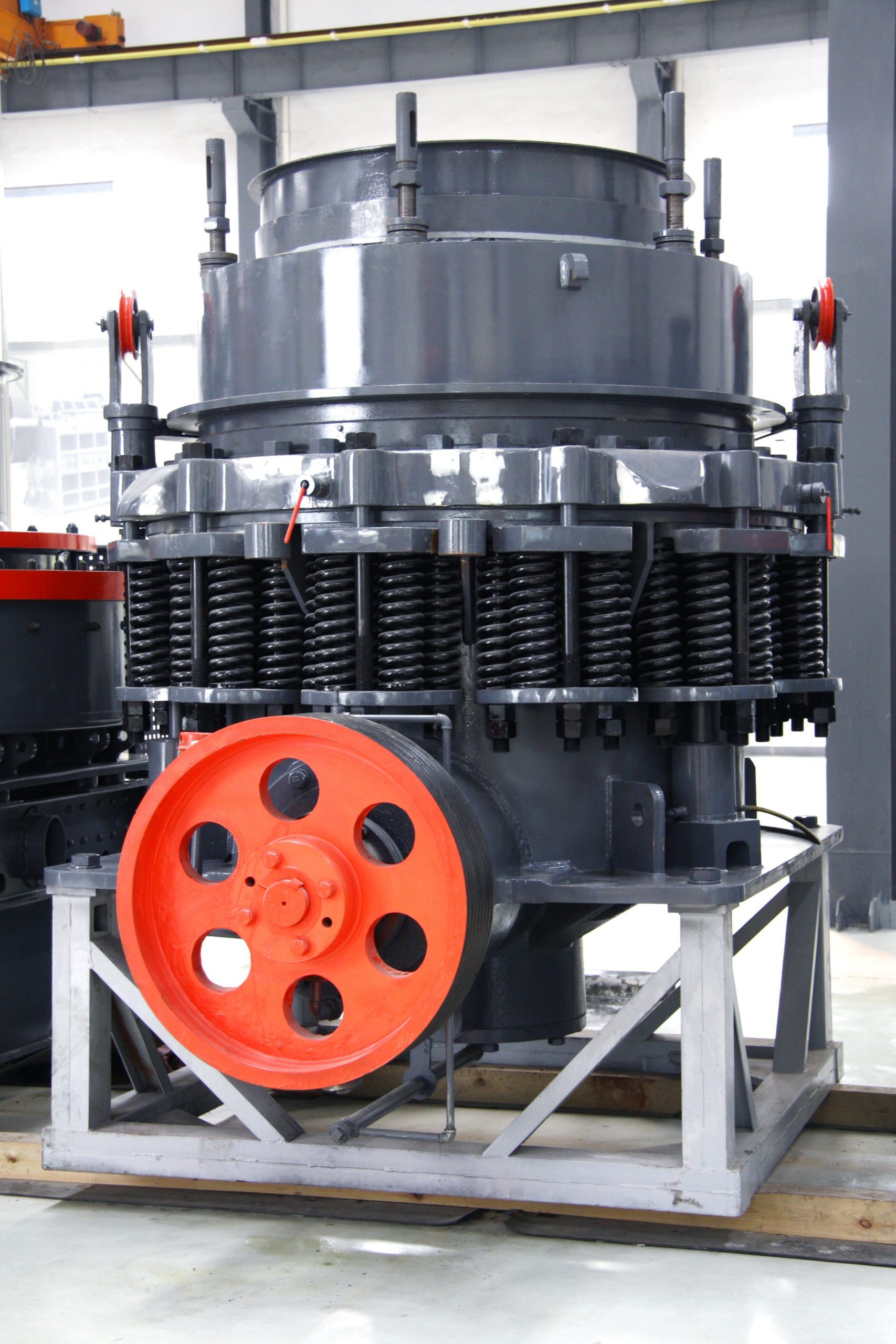

The Symons cone crusher is a type of compression crusher that reduces material by squeezing or compressing it between a moving piece of steel and a stationary piece of steel. It is widely used in mining, aggregate, and construction industries for secondary and tertiary crushing.

- Mining: For crushing ores and rocks of medium to hard hardness.

- Aggregate Production: For producing gravel, sand, and other aggregates.

- Construction: For reducing building materials and demolition debris.

- Industrial: For crushing a variety of industrial materials, including chemicals and ceramics.

Key Components:

- Frame: The main structure supporting all other components.

- Mantle: The moving part of the crusher that gyrates in an eccentric motion.

- Concave: The stationary part that the mantle crushes against.

- Eccentric Assembly: Provides the gyrating motion to the mantle.

- Adjusting Ring: Adjusts the size of the output material by changing the gap between the mantle and concave.

- Hydraulic System: Used for clearing the crushing chamber if an uncrushable material enters and for adjusting the crusher setting.

Working Principle:

- Material Feed: Material is fed into the crusher through the top.

- Crushing Process: The mantle moves eccentrically, compressing the material against the concave. The material breaks and falls to a lower position in the chamber where it is compressed again. This process continues until the material is small enough to exit through the bottom of the crusher.

- Output Size: The final product size is determined by the gap between the mantle and the concave, which can be adjusted.

Advantages:

- High Crushing Efficiency: Provides high reduction ratios and high throughput.

- Durability: Designed for long-term operation with minimal maintenance.

- Versatility: Suitable for a variety of materials and applications, including hard and abrasive materials.

- Uniform Product Size: Produces a consistent and high-quality output.

Specifications:

| Model | Cavity Type | Crushing Cone Dia.(mm) |

Adjusting Range of Discharge Opening(mm) |

Max feeding size (mm) |

Capacity (t/h) |

Motor (kw) |

Overall size (mm) |

| CS75 | C | 900(3′) | 13-38 | 150 | 59-163 | 75 | 2656×1636×2241 |

| CS75 | M | 900(3′) | 9-22 | 85 | 45-91 | 75 | 2656×1636×2241 |

| CS75 | F | 900(3′) | 3-13 | 35 | 27-90 | 75 | 2656×1636×2241 |

| CS110 | C | 1200(4′) | 19-50 | 180 | 110-250 | 110 | 2821×1974×2651 |

| CS110 | M | 1200(4′) | 13-38 | 130 | 80-180 | 110 | 2821×1974×2651 |

| CS110 | F | 1200(4′) | 9-31 | 90 | 63-140 | 110 | 2821×1974×2651 |

| CS160 | C | 1295(4 1/4′) | 19-51 | 205 | 172-349 | 160 | 2983×1866×3156 |

| CS160 | M | 1295(4 1/4′) | 16-38 | 178 | 132-253 | 160 | 2983×1866×3156 |

| CS160 | F | 1295(4 1/4′) | 13-31 | 115 | 109-181 | 160 | 2983×1866×3156 |

| CS220 | C | 1400(4 1/2′) | 30-60 | 235 | 210-530 | 220 | 3360x2650x3050 |

| CS220 | M | 1400(4 1/2′) | 22-45 | 180 | 180-475 | 220 | 3360x2650x3050 |

| CS220 | F | 1400(4 1/2′) | 19-40 | 100 | 130-260 | 220 | 3360x2650x3050 |

| CS250 | C | 1650(5 1/2′) | 25-64 | 228 | 299-635 | 250 | 3941×2954×3771 |

| CS250 | M | 1650(5 1/2′) | 22-51 | 205 | 258-417 | 250 | 3941×2954×3771 |

| CS250 | F | 1650(5 1/2′) | 16-38 | 178 | 181-327 | 250 | 3941×2954×3771 |

| CS315 | C | 2135(7′) | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | M | 2135(7′) | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | F | 2135(7′) | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |