Description

Introduction

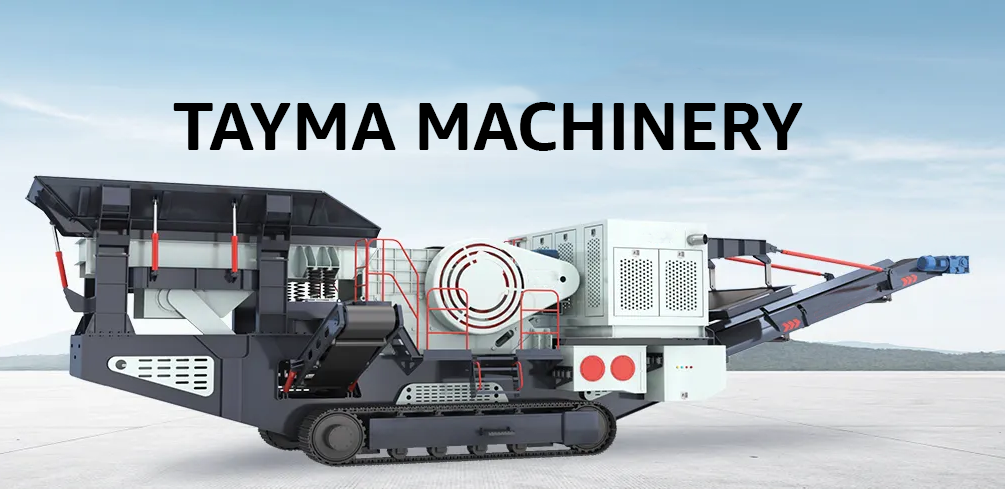

A crawler jaw crusher, also known as a mobile jaw crusher, is a type of portable crushing plant that combines a jaw crusher with crawler tracks for mobility. This combination allows the crusher to move easily over rough terrain and to different job sites, making it highly versatile and efficient for various applications in mining, quarrying, and construction. Here are the key features and benefits of a jaw crawler crusher:

Key Features

- Jaw Crusher: The core component is a jaw crusher, which uses compressive force to break down materials. The material is fed into a V-shaped crushing chamber and compressed between a fixed jaw and a moving jaw.

- Crawler Tracks: Mounted on tracks, which provide excellent stability and mobility over various terrains. This track system allows the crusher to be moved to different locations on a job site or between sites.

- Hydraulic Drive: Utilizes a hydraulic drive system for powerful and smooth operation, making it easy to maneuver and adjust.

- Feed Hopper: Large feed hopper to handle substantial amounts of material, which can be fed into the crusher either manually or via an excavator.

- Conveyor Belts: Includes conveyors for transporting crushed material from the jaw crusher to a secondary crushing stage or to a stockpile.

Benefits

- Mobility: Can be easily transported and relocated, reducing transportation costs and time.

- Versatility: Suitable for a wide range of applications, including primary crushing in mining, quarrying, and construction.

- Efficiency: High crushing capacity and performance, with the ability to crush large quantities of material quickly and effectively.

- Flexibility: Adjustable settings allow for different material sizes and output requirements.

- Reduced Environmental Impact: Equipped with dust suppression systems and often designed to minimize noise pollution, contributing to a safer and more environmentally friendly worksite.

Applications

- Mining: Crushing ore and rock for processing.

- Quarrying: Breaking down large rocks into smaller, more manageable pieces.

- Construction: Crushing concrete and other demolition debris for recycling.

- Infrastructure Projects: Providing crushed material for road construction, bridge building, and other infrastructure projects.

Performance advantage

- The crawler chassis is easy to drive in the rugged and harsh road environment of the crushing site, saving time for quick entry to the construction site

- The integrated unit configuration is convenient and reasonable for installation and maintenance, which makes the configured unit have high durability and higher working time

- The installation form of integrated unit equipment eliminates the complicated site infrastructure installation work of split components and reduces the consumption of materials and man-hours

- The machine has high crushing efficiency, powerful functions, light and reasonable structure design, and stable and reliable quality.

Working principle

The material is evenly conveyed into the crusher through the feeder. After the primary crushing by the jaw crusher, a closed-circuit system is formed by the circular vibrating screen to realize the circular crushing of the material. The finished material is output by the conveyor for continuous crushing. The jaw crusher mobile crushing station can remove the circular vibrating screen according to actual production needs, so as to realize the direct primary crushing of materials, and it is convenient and flexible to use with other crushing equipment.

Technical Parameters

| Model | Feeder | Jaw Crusher | Main Discharge Belt | Side Discharge Belt | Capacity |

|---|---|---|---|---|---|

| YMC80 | G2D8035 | C80 | B800x9m | B500x3.8m | 80-125t/h |

| YMC96 | G2D9638 | C96 | B1000x12m | 100-250t/h | |

| YMC106 | G2D1142 | C106 | 160-360t/h | ||

| YMC116 | C116 | B1200x13m | 200-450t/h | ||

| YMC120 | G2D1242 | C120 | 300-520t/h |