Description

Process Description

1. Stages grinding and separation improves concentrate indexes

Mixed roughing after the coarse grinding, then regrinding the coarse concentrate and cleaning; the small quantity of regrinding crude concentrate makes monomer dissociation and save energy consumption while obtaining high grade concentrate and high recovery rate.

2. Strengthen flotation process improves molybdenum concentrate grade

Strict implementation of agent system in roughing and control agent dosage to reduce the loss of many cycles; make full use of the twice enrichment of bubble; washing concentrate foam to reduce the impurity in foam flotation.

3. Stage-processing to Guarantee the Recovery Rate

Stage-processing is applied to recover valuable minerals in different particle sizes as possible to improve the concentrate indexes.

4. Combining Processing Technology and Equipment

TAYMA can provide the whole set of equipment for the production line, guaranteeing the fitness of equipment and processing technology.

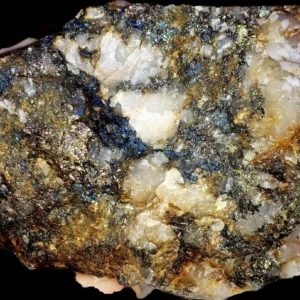

Introduction

A molybdenum dressing production line is utilized to extract and process molybdenum ores to produce molybdenum concentrate. This concentrate is then used for various applications in different industries. Here are the primary uses of molybdenum and the applications of a molybdenum dressing production line:

Uses of Molybdenum

- Alloy Production:

- Steel Alloys: Molybdenum is used as an alloying agent in the production of high-strength steel and stainless steel. It enhances strength, toughness, and resistance to wear and corrosion.

- Superalloys: Used in the aerospace and defense industries, superalloys containing molybdenum can withstand extreme temperatures and stress.

- Chemical Applications:

- Catalysts: Molybdenum is used in chemical catalysts, particularly in the petroleum industry for refining oil and removing sulfur from fuels.

- Pigments: Molybdenum compounds are used as pigments in inks, paints, and dyes.

- Electronics and Electrical Applications:

- Semiconductors: Molybdenum is used in semiconductor materials and thin-film transistors.

- Electrical Contacts: Due to its high conductivity and resistance to heat, molybdenum is used in electrical contacts and filaments.

- Lubricants:

- Molybdenum Disulfide: This compound is used as a dry lubricant in various industrial applications where high temperatures or high pressures are involved.

- Glass and Ceramics:

- Glass Production: Molybdenum is used in glass furnaces and the production of specialized glass products.

- Ceramic Glazes: It is used in ceramic glazes for its color and durability.

- Medical Applications:

- Medical Implants: Molybdenum’s biocompatibility makes it suitable for use in medical implants and devices.