Description

Process Description

1. Gravity Separation

For the gravity separation of barite, the process of TAYMA is crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. The jig is the main equipment for the separation and purification of barite ore, which is energy-saving, high efficiency, and environment protection. In the process of crushing, TAYMA uses the jaw crusher and applies a two-stage crushing process. In the process of screening, TAYMA uses a simple and useful circular vibrating screen, which also has the features of large capacity, high efficiency, and convenient operation. It is very suitable for screening of barite ore. In the process of jigging, TAYMA applies two kinds of jigs to respectively separate the coarse and fine granularity of barite material.

2. Magnetic Separation

TAYMA usually applies wet magnetic separation to beneficiate some iron-bearing mineral, like siderite, which applies to barite ore that is used in barium-based medicine requiring low iron barite.

3. Floatation

As for the barite with fine particle size and gravity tailings, TAYMA applies the process of floatation. According to the different adsorption manner, TAYMA uses some anionic collectors, like fatty acid alkyl sulfate, alkyl sulfonate, or cationic collector, like amide collectors to do the floatation for barite ore.

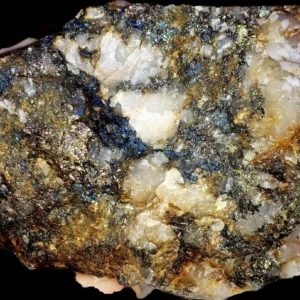

Introduction

A barite mineral production line is utilized to extract and process barite ore into barite concentrate, which is used in various industries due to its unique properties. Here are the primary uses of barite and the overall utility of a barite mineral production line:

Uses of Barite

- Oil and Gas Industry:

- Drilling Mud: Barite is primarily used as a weighting agent in drilling muds for oil and gas exploration to control wellbore pressure, prevent blowouts, and maintain well stability.

- Medical Industry:

- Radiology: Barite is used in barium sulfate form as a contrast agent for X-ray imaging and other diagnostic procedures in the gastrointestinal tract.

- Paints and Coatings:

- Pigment Extender: Barite is used as a pigment extender in paints and coatings to enhance brightness and improve durability.

- Rubber and Plastics:

- Filler Material: Barite is used as a filler in rubber and plastic products to increase weight and improve soundproofing and resistance to wear.

- Construction:

- Heavy Aggregate: Barite is used as a heavy aggregate in concrete for construction projects requiring high-density concrete, such as radiation shielding.

- Chemicals:

- Barium Compounds: Barite is used to produce various barium compounds, such as barium carbonate and barium chloride, used in chemical applications.

- Paper and Textile:

- Filler and Brightener: Barite is used as a filler and brightener in the paper and textile industries to improve the quality of products.

- Cosmetics:

- Cosmetic Products: Barite is used in cosmetics as a filler and to provide weight and opacity.