Description

Introduction

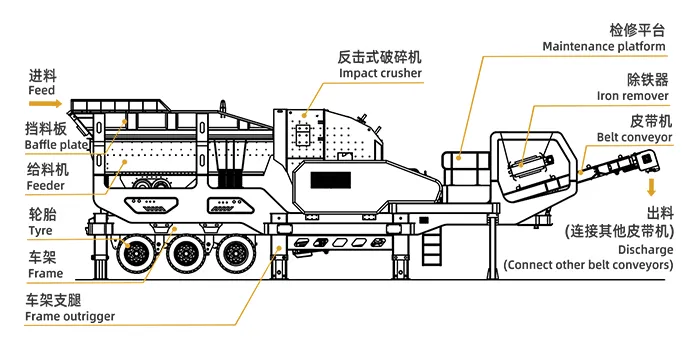

The mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equipped with vibrating feeders, vibrating screens, conveyor belts, and other equipment. It can be flexibly moved between different construction sites and is suitable for processing construction waste, rocks ore, and other materials.

Applications

- Mining: In the mining industry, mobile impact crushing stations are often used to crush ore. Due to its strong mobility, it can be easily moved along with the mining progress of the mine, making the crushing operation more efficient and convenient.

- Construction waste disposal: With the acceleration of urbanization, the disposal of construction waste has become a big problem. The mobile impact crushing station can crush construction waste into recycled aggregates of different sizes and specifications, realizing the resource reuse of construction waste, which is of great significance to environmental protection and sustainable development.

Working principle

First, raw materials (such as ores, rocks, construction waste, etc.) are fed into the silo of the mobile impact crushing station through forklifts, excavators, and other equipment. These raw materials then enter the screening feeder, where the smaller part of the raw materials will leak directly through the screen holes and be directly formed into mounds or further processed by the excavating belt conveyor.

Materials with larger particle sizes continue to enter the impact crusher through the screening feeder. In the impact crusher, the motor drives the rotor to rotate at high speed through the triangle belt. The plate hammer on the rotor radiates under the action of centrifugal force. When the material enters the rotating range of the plate hammer, it is impacted by the high-speed rotating plate hammer. The material is thrown to the impact plate along the tangential direction of the plate hammer for impact. This impact process causes the material to be continuously impacted and squeezed in the crushing cavity, causing damage to its internal organization, thereby achieving crushing.

Specifications

| SMC Impact crusher | SMC1010PFS | SMC1210PFS | SMC1214PFS |

| Transport size | |||

| Length(mm) | 10800 | 12200 | 12500 |

| Width(mm) | 2480 | 2743 | 2900 |

| Height(mm) | 4170 | 4200 | 4200 |

| Alex weight(kg) | 15900 | 17200 | 22100 |

| King pin weight(kg) | 11300 | 14300 | 17500 |

| Impact crusher | |||

| Model | PF1010 | PF1210 | PF1214 |

| Feed opening(mm) | 400X1080 | 400X1080 | 400X1080 |

| Vibrating screen | |||

| Model | 4YK1235 | 4YK1545 | 4YK1548 |