Description

Introduction

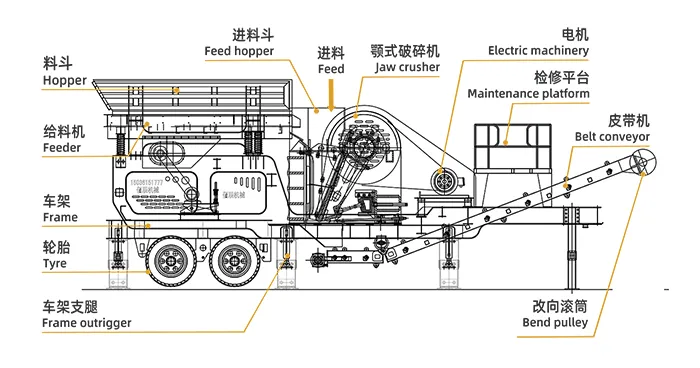

Mobile jaw crusher station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the customer’s standpoint, take the elimination of obstacles to customers’ crushing operations caused by the crushing site and environment as the primary solution, and truly provide customers with efficient and low-cost project operation hardware facilities.

Working principle

The main working parts of the mobile jaw crushing station include two jaw plates, one is a fixed jaw plate (fixed jaw) and the other is a movable jaw plate (movable jaw). These two jaw plates simulate the movement of the two jaws of an animal. The motor drives the belt and pulley, causing the movable jaw to move periodically.

When the motor drives the eccentric shaft to rotate, the movable jaw moves up and down accordingly. When the movable jaw rises, the angle between the movable jaw and the fixed jaw becomes larger, causing the movable jaw plate to approach the fixed jaw plate. The material is clamped between the two jaw plates and is subjected to multiple crushing forces such as squeezing, rubbing, and grinding. thereby achieving fragmentation. When the movable jaw descends, the angle between the two jaw plates becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the spring, and the crushed material is discharged from the discharge port at the lower part of the jaw cavity under the action of gravity.

The mobile jaw crushing station realizes batch crushing of materials by continuously performing the above crushing process. In addition, the mobile jaw crushing station is also equipped with auxiliary equipment such as feeding, screening, and conveying to form a complete crushing production line.

Application

Mobile jaw crushing plant have been widely used in many industries and fields due to their advantages such as high efficiency, flexibility, and environmental protection. Whether it is mining, road construction or urban demolition, it can exert excellent crushing effects and provide strong support for various projects.

Specifications

| Model | SMC600 | SMC750 | SMC900 | SMC1060 | SMC1200 | SMC1300PEX |

| Transport size | ||||||

| Length(mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

| Width(mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

| Height(mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

| Alex weight(kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

| King pin weight(kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

| Jaw crusher | ||||||

| Model | PE | PE | PE | PE | PE | PEX |

| Feed opening(mm) | 400X600 | 500X750 | 600X900 | 750X1060 | 900X1200 | 300X1300 |

| Discharging hole setting range(mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

| Capacity(t/h) | 15-60 | 40-110 | 90-180 | 110-380 | 220-450 | 30-105 |

| Feeder | ||||||

| Feed hopper volume | 3 | 4 | 7 | 10 | 10 | 3 |

| Hopper width | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

| Model | ZSW6520 | ZSW8530 | ZSW9638 | ZSW1142 | ZSW1349 | ZSW8530 |

| Belt conveyor | ||||||

| Model | B650X6 | B800X7 | B1000X8 | B1000X11 | B1200X13 | B1000X7 |