Description

Process

The calcium carbonate grinding production line provides an efficient, environmentally friendly, and stable solution for the production of calcium carbonate powder, meeting the needs of different industries for calcium carbonate powder.

- Raw material crushing: The calcium carbonate bulk material is first crushed through a crusher to a fineness suitable for feeding into the grinding mill. Usually, this fineness ranges from 15mm to 50mm.

- Grinding: The crushed calcium carbonate small pieces are sent to the silo through the elevator and then sent to the grinding chamber of the mill evenly and quantitatively through the conveying equipment for grinding. This stage can be accomplished by using equipment such as a Raymond mill or a vertical mill.

- Grading: The ground materials are accurately classified through the powder separator. The unqualified powder will be classified by the powder selection machine and then returned to the main machine for re-grinding to ensure that the final product particle size meets the requirements.

- Powder collection and packaging: Powder that meets the fineness requirements will enter the dust collector through the pipe with the airflow for separation and collection. The collected finished powder is sent to the finished product silo through a conveyor and then packaged using a powder tanker or automatic baling machine.

Introduction

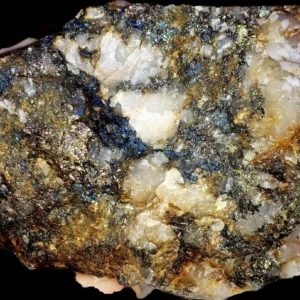

A Calcium Carbonate Grinding Production Line is a system designed to process calcium carbonate (CaCO₃) into fine powders for various applications. Calcium carbonate is a common mineral found in rocks such as limestone, marble, and chalk. The production line consists of several stages and pieces of equipment to achieve the desired fineness and quality of the calcium carbonate powder.

Benefits of Calcium Carbonate Grinding Production Lines:

- High Efficiency: Advanced grinding technologies ensure high production efficiency.

- Fine and Consistent Powder: Precision in grinding and classification ensures consistent product quality.

- Environmental Protection: Dust collection systems minimize environmental impact.

- Versatility: Suitable for producing calcium carbonate powder for various applications.

Applications:

- Plastics and Rubber Industry: Used as a filler to improve material properties and reduce costs.

- Paint and Coatings: Provides a smooth finish and improves the durability of paints.

- Paper Industry: Used as a filler and coating pigment to enhance paper quality.

- Construction Materials: Added to cement and concrete to improve strength and durability.

- Pharmaceuticals: Used as an inactive ingredient in tablets and other formulations.

By processing calcium carbonate into fine powder, this production line supports various industries by providing a versatile and essential material for manufacturing processes.