Description

| Description | Unit | HT4000 | HT6000 | HT8000 |

| Paving width | mm | 3000-4150 | 500-6100 | 3500-8000 |

| Paving thickness | mm | 0-450 | 0-450 | 500 |

| Paving speed | m/min | 0-10 | 0-8 | 0-7.5 |

| Travelling speed | km/h | 0-1.5 | 0-1.5 | 0-1.2 |

| Vibrator bar | High frequency hydraulic drive | |||

| Engine

Power |

Option 1

kW/rpm |

Cummins

119/2200 |

Cummins

163/2200 |

Cummins

194/2200 |

| Option 2

kW/rpm |

– | Volvo

160/2200 |

Volvo

185/2200 |

|

| Drive system | hydraulic drive | hydraulic drive | hydraulic drive | |

| Overall size | mm | 4000x5300x2800 | 4000x7300x2800 | 4000x9300x2800 |

| Machine weight | kg | 18000 | 26000 | 34000 |

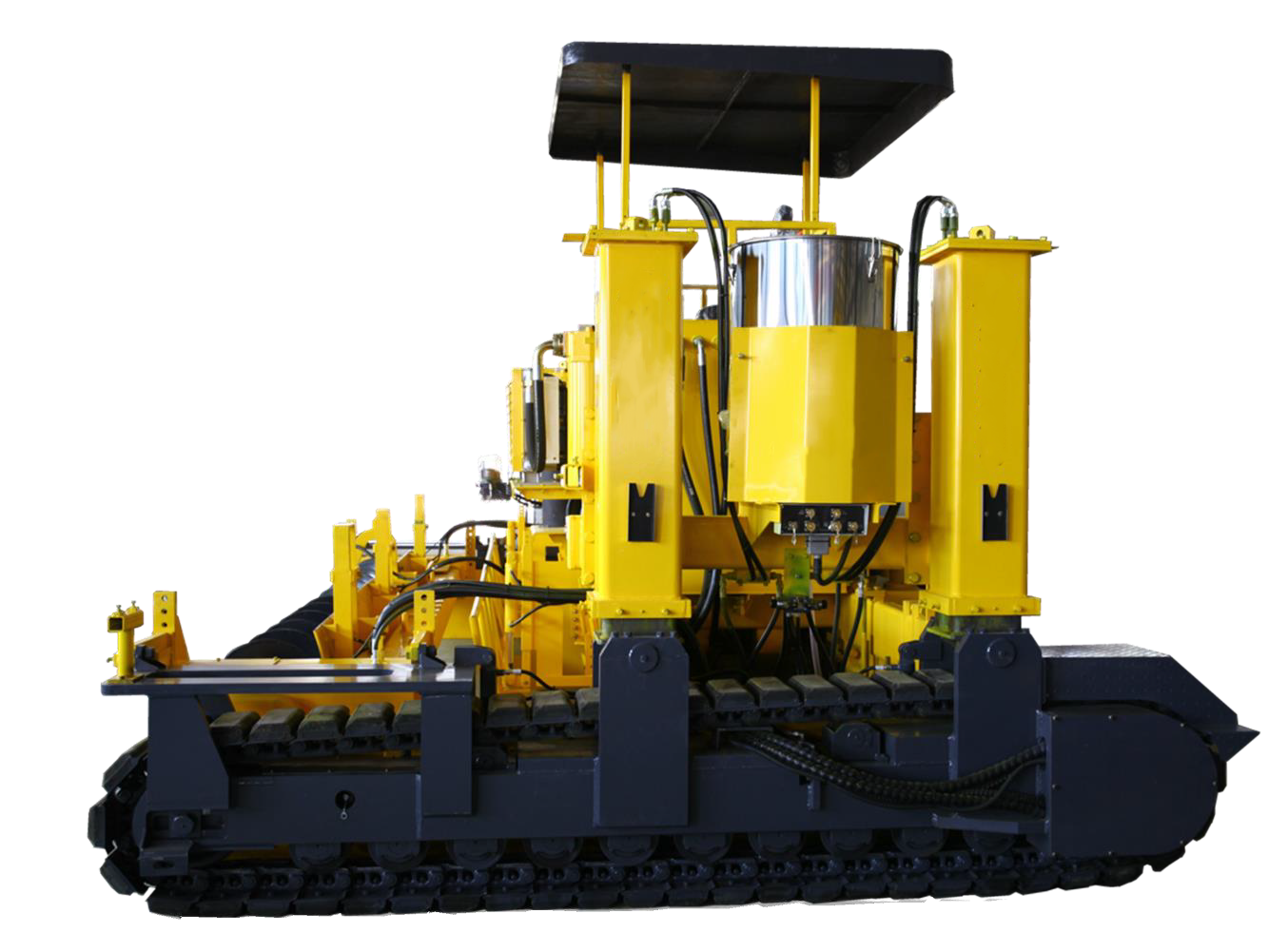

Working Principle of Slipform Concrete Paver

The slipform paver operates by continuously moving forward while receiving a steady supply of concrete from trucks or other sources. As the machine advances, it spreads and levels the concrete using its integrated components. The vibrating screed ensures that the surface is uniformly leveled, while the finishing equipment provides the desired texture and appearance. This continuous process results in efficient and high-quality concrete paving, making it an essential tool in large-scale construction projects.

Advantages of Using Slipform Concrete Paver

- Efficiency: The slipform paver’s continuous operation allows for rapid progress in paving large areas, contributing to project efficiency and timely completion.

- Precision: The machine’s design and components enable precise control over concrete placement and finishing, leading to high-quality surfaces with minimal deviations.

- Cost-Effectiveness: By streamlining the paving process and reducing manual labor requirements, slipform pavers offer cost-effective solutions for large-scale concrete construction projects.

- Quality Control: The use of slipform pavers ensures consistent quality across the paved surface, meeting industry standards and specifications.

- Versatility: These machines can be adapted for various paving widths and thicknesses, making them suitable for diverse project requirements.

Features

| 1. Engine

Volvo / Cummins water-cooled engine, powerful, high-torque reservation, low fuel consumption, emission in conformity with Europe environment. |

4. Scraping Plate

Controlled through two hydraulic cylinders to control concrete quantity incoming to shaping-template, which could go up & down wholly or up & down independently at either lh or rh. |

| 2. Vibration Device

Super-high frequency, strong vibration, high density of top-side paving . |

5. Travelling System

Two hydraulic-drive crawlers and microcomputer control ensure pre-set constant speed, correct straight-line running and smooth steering at bends. |

| 3. Auto Levelling System

Auto levelling and tracing systems ensures paving surface flatness and road straightness. |

6. Centralized Lubrication

Centralized lubrication can auto. Charge lubrication grease to high-temperature and motive components, lengthen wear-out period effectively, greatly improve reliability of tamper and feeding. |

Equipment

| Standard | Optional |

| 1. Hydraulic vibrators

The paver comes standard with 14 hydraulic connections to power the hydraulic vibrators (9 or 24 optionally available) |

1. Optional super smoother

The super smoother made of high-quality material ensures perfect surface quality |

| 2. Separate side bar inserters

Side tie bar inserters on the equipped on both sides automatically insert tie bars to pave adjacent road pavements |

2. Optional Oscillating beam inserter

The eccentric -powered, heavy-duty oscillating beam with automatic lifting function when the machine stops can remove any irregularities in the concrete pavement surface. |

| 3. Longitudinal tie bar inserter

Longitudinal tie bars are inserted automatically to prevent the slabs from drifting apart at the longitudinal joints. |